HYCOOL

The Industrial Solar Cooling Solution

Yes, solar heat can power industrial processes.

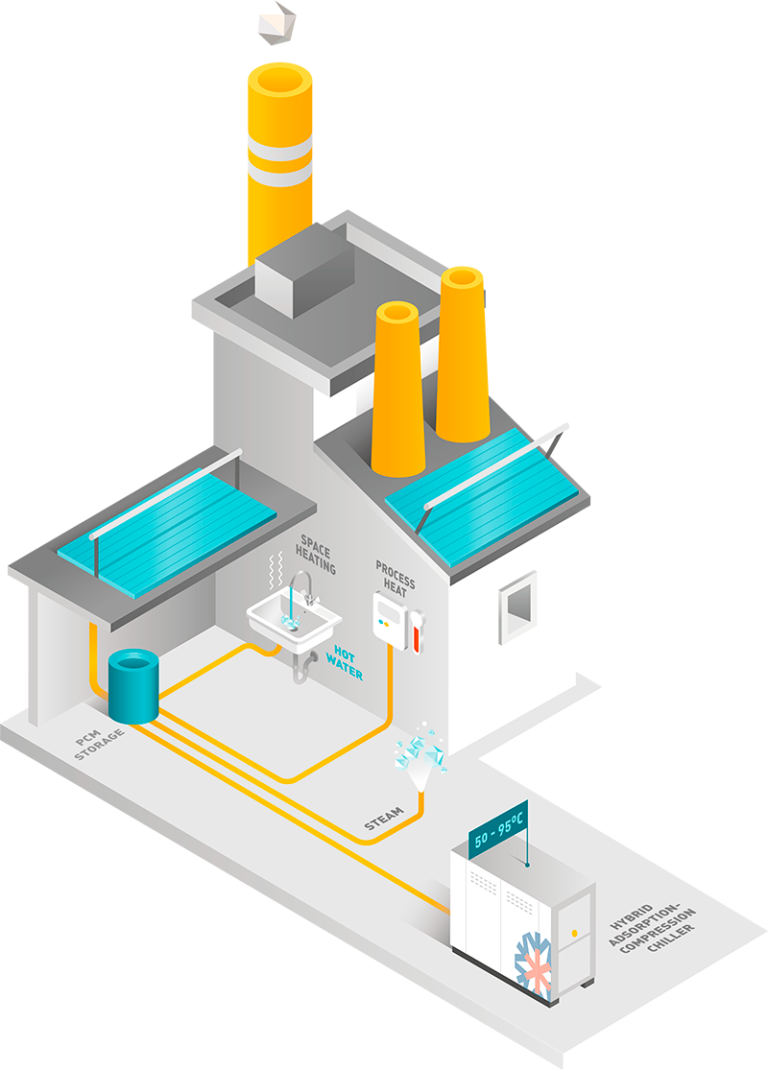

By combining solar collectors with adsorption chillers, solar energy can be used to produce steam, heating, and cooling energy with greater efficiency.

The HyCool Project Mission

To Increase the Use of Solar Heat in Industrial Processes

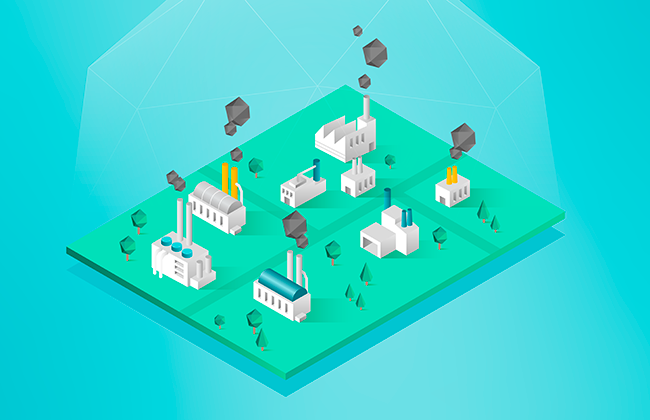

Two-thirds of industrial energy consumption is related to heating and cooling processes and is becoming a major environmental problem. The integration of renewable thermal energy sources at industrial sites is therefore crucial.

In this context, the EU co-financed HyCool project aims to increase the use of solar heat in industrial processes by combining two key components: Fresnel solar thermal collectors and hybrid adsorption-compression chillers to provide steam, heating, and cooling energy with greater efficiency.

A 4-YEAR INNOVATION ACTION PROJECT

FUNDED BY THE EU’S HORIZON 2020 PROGRAMME

4

YEARS

15

PARTNERS

10

EU COUNTRIES

2

PILOT SITES

9

MILLION BUDGET

What Will Be the Impact of Hycool?

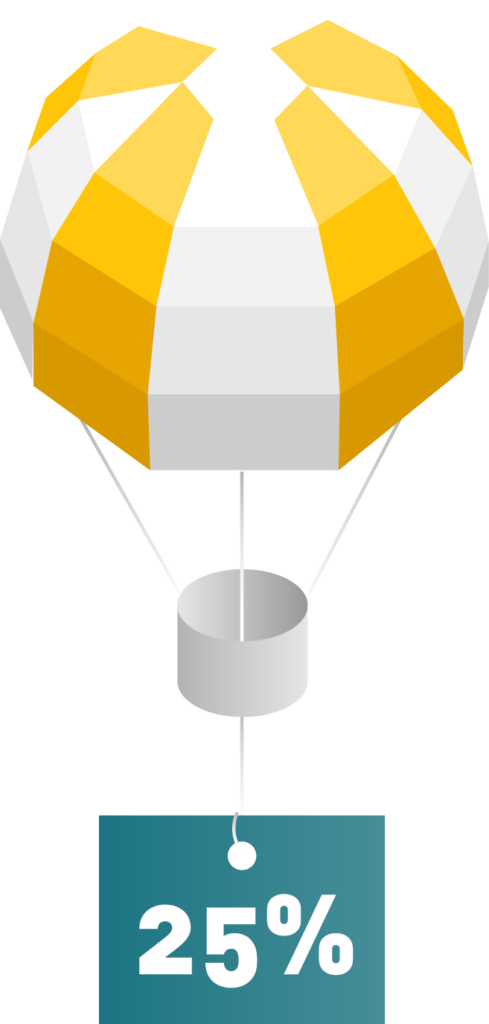

This can bring significant prospects for the market uptake of this renewable energy source and for the decarbonization of the industrial sector. By offering to reduce energy consumption by 75% and increase energy efficiency by 25%, HyCool aims to double solar cooling installations worldwide, 5 years post-project.

Our innovations

LEADING TECHNOLOGY AND INNOVATION MAKES HYCOOL

THE SOLAR COOLING SOLUTION FOR GREEN

AND ENERGY-EFFICIENT INDUSTRIAL PROCESSES

The hybrid chiller within HyCool will allow a step forward towards the exploitation of thermally driven cooling systems in industrial applications. It will take advantage of the renewable solar heat source to drive a sorption module, thus increasing the electric efficiency of a vapour compression chiller.

Through a patented innovation, the Concentrated Solar Panels (CSP) used will be able to significantly reduce the system costs compared to existing technologies while reducing the complexity of integration. The thermal performance of the system prototype has been proved by a solar testing institute with good results.

Thermal energy storages are a vital means to increase the share of intermittent renewable energies and to enhance waste-heat recovery in industries with non-continuous processes. Therefore they help mitigate CO2 emissions by allowing for demand side management and load shifting.

An innovative methodological approach that will allow for the exchange of the real-monitoring data gathered from the pilots with their related Asset Information Model (AIM) digital twins in a virtual reality environment.

In HyCool, this will help maximise the impact in communication & dissemination, allowing for such activities as virtual tours through the VR Models during fairs and online channels or the development of innovative onsite trainings using augmented reality tools and real time data.

DEMO SITES

Our aim is to demonstrate the potential of solar cooling systems for industries.

For this, our pilot sites will implement the HyCool system through opposite strategies

in two selected key industrial sectors: food and chemicals.

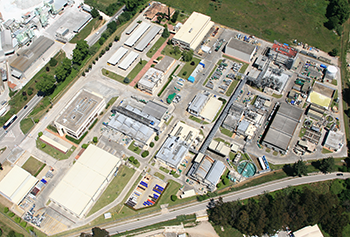

Givaudan

Chemical Industry

The chemical case pilot targets industries with several processes in high solar irradiation areas with steam and cooling needs. Givaudan’s cold installation makes use of a glycolic water chiller to keep the water entering the liquid ring of the vacuum pumps at 7oC. The thermal demand for the installation was calculated at 125.5 kW.

Bo de Debò

Food Industry

The food case pilot targets specialized small food industries in high solar irradiation areas with cooling needs in their processes. Here the industrial cold installation is necessary for the good preservation of the product, it serves different rooms to achieve the following final temperatures in the chamber: Production area: 6-8oC Delivery area: 10-12oC.

HYCOOL NEWS & PUBLICATIONS

of our latest project’s findings and events.

Start of the works to launch the pilots!

At the end of last September, the pilots of the HyCool project (Industrial Cooling through Hybrid system based on solar heat) began their way to start-up…

HYCOOL scientific poster and paper for EuroSun 2020

On September 1st , 2020, HYCOOL partner, CNR ITAE, presented the project at EuroSun 2020. EuroSun 2020 offers a platform to discuss the latest developments…

We have been showcased @CORDIS_EU

Our project aiming to increase the use of solar heat in industrial processes has been featured at cordis.europa.eu, the European Commission’s primary source of results, news…