Technologies & Ker

Discover Our Technological Impact on the Solar Cooling and Ship Sectors!

The market potential of solar technologies for industrial application is growing and the HyCool project is proposed as a necessary tool to bridge the gap between market needs and the best technologies available in the research field. Find out here about HyCool technological innovations and their most relevant exploitable results!

HyCool's Solar Thermal Concentrator

The HyCool solar thermal concentrator being developed by ECOTHERM is:

- 100% renewable.

- Efficient and enables flexible utilization of solar thermal energy.

- Manages storage capacities and loads on different temperature levels.

- Considers weather forecasting and power tariffs for optimization.

- Based on a proprietary algorithm and patented moving mechanism.

- Rooftop installation is possible.

- Can exchange information through a cloud-based interoperable data exchange server.

HyCool uses a concentrating technology based on ECOTHERM’s novel Fresnel collectors that have been specifically designed to offer a compact and easy-to-install system, in order to ensure successful small-scale installations (from a technical and economic perspective).

ECOTHERM’s system is based on flat mirror modules, which consist of narrow stripes of tempered glass directly glued onto silicon line hinges (patented innovation), without any extra mechanical mirror support (as used by all competitors). By using such a flat system (module height < 20 cm), this technology offers three substantial advantages when compared to PTC concentrators or other Fresnel technologies: reduced wind exposure, which results in avoiding complex system foundations or substructures to withstand wind forces effectively; and reduced on-site installation costs, as the patented innovation allows an automated pre-manufacturing of the technology.

All the key components of the collector, as well as its main alignment activities, are fulfilled on the factory and avoided on-site; and maximized ground usage ratios, as narrow mirror stripes have a reduced shadowing effect among themselves and allow a separation between mirror stripes of only some millimetres, thus enabling a very high density of mirror area per ground area. This also enables both ground and rooftop installations.

HyCool's Hybrid Heat Pumps

The HyCool Hybrid Heat Pumps being developed by FAHRENHEIT & CNR are:

- Unique, flexible, and efficient.

- Can access the demand response market.

- Can reach negative temperatures

- The refrigerant in the adsorption heat pump is pure water – non-toxic, non-flammable, safe for the people, and good for our environment (ODP=0, GWP=0).

- The refrigerant in the compression heat pump is propane – natural refrigerant, much less harmful for our environment than synthetic ones (ODP=0, GWP=3).

- The adsorption heat pump is powered by heat (from renewable sources or waste heat) – reduces the electricity consumption for cooling and increases the overall energy efficiency of the plant.

- The adsorption heat pump has no moving parts and no over-pressure in the process modules, which means simple installation, robust and silent operation, longevity, and low maintenance requirements. By combining adsorption and compression, it is possible to reduce the electricity consumption for cooling and to provide cooling at temperatures below the standard operating range for adsorption chillers (below 8°C), while covering peak demand even at high ambient temperatures.

HyCool's Energy Management System

ECOTHERM uses an improved energy management system that allows the analysis of multiple parameters to define in each moment the most beneficial energy flows. The availability of solar energy is the first key parameter, as the maximum utilization of solar energy is usually preferential. Based on an energy forecasting algorithm (including power and fuel tariffs, weather forecasts, daily consumption profiles of the industry), the energy management system of Ecotherm automatically determines the best variables of the system to obtain the highest efficiency. The energy management system includes full monitoring and live-visualization of the energy flows and decisions, as well as a cloud-based interoperable data exchange server.

The Energy management feature developed for HyCool is specifically designed to optimize the use of solar thermal energy and is NOT like any kind of building optimization. This is the difference to the energy management systems offered by the big market players like ABB, Siemens, Jonson Control, or Schneider Electric. The term “energy management” is used for a wide spectrum of activities in the field of energy savings. While the ISO50001 called “energy management systems” describes a standardised strategy on how to implement energy-saving activities as a “Plan-Do-Check-Act” process, the energy management system developed for HyCool is limited to a software feature for the integration of solar thermal energy in industrial processes.

Phase Change Materials Energy Storage

The PCM Energy Storage being developed by AIT are:

- Versatile in terms of power and application temperature. PCMs are available up to 500 °C. The storage in HyCool is based on special durable steel alloys that enable also such high-temperature storage even if within this project we demonstrate only up to 230 °C.

- Suitable for requirements for renewable heat systems, process heat, district heating, power generation, and domestic heating.

- Scalable. The PCM storage solutions further developed in HyCool are “modular solutions”, i.e. one can combine many modules of 100 kWh each to achieve almost arbitrary total storage capacity. Storage on the scale of many 100 MWh is easily possible using this modular attempt.

- High heat density (we prefer the term high energy density actually).

- Manufactured in a low-cost, sustainable material as it can be produced from renewable biological sources and/or the professional recycling industry.

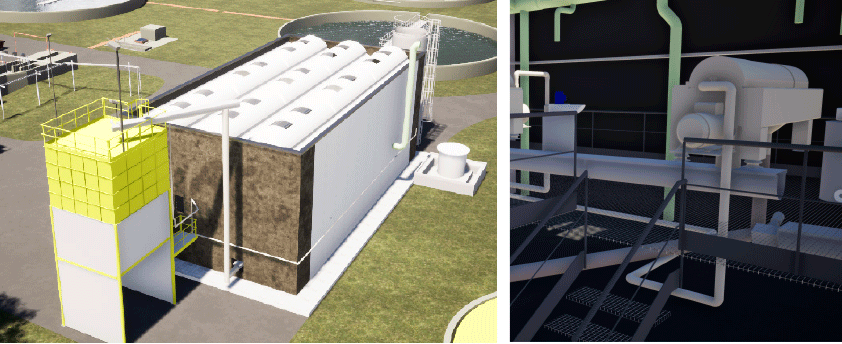

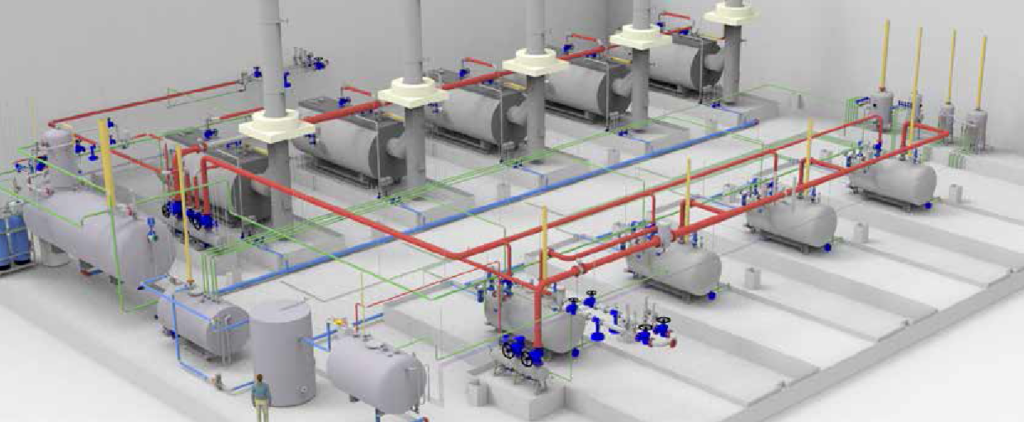

BIM-based Digital Twins for Real-time Monitoring & Training

HyCool will use BIM-based Digital Twins in a virtual reality environment for real-time monitoring & innovative onsite training using virtual reality (VR) tools:

VR is based on BIM (building information modelling) and digital twins as an asset management tool in industrial environments, a BIM + Asset manager tool in HyCool can provide both, a rich information model interactive and accessible in a 3D view environment by means of screens and lenses or intelligent glasses and also augmented reality, therefore, at IDP we are doing something very close to the digital twin of technical rooms in HyCool, all the modeling is made in BIM and the machines and systems

are integrated from the models made by equipment manufacturers, therefore it would be a DTwin with a potential capacity to connect the sensors and the time series of data if available to create real-time or quasi-real-time experiences.

To complete the previous idea, the real-time monitoring functionality may or not be included in the VR because there will be a limitation to the connection with SCADA or other centralised control systems in the pilot sites. Therefore, some operational history of the tool could be shown, but for consultation or lessons learned so that the user can see a solution to a specific problem.