Article by Givaudan

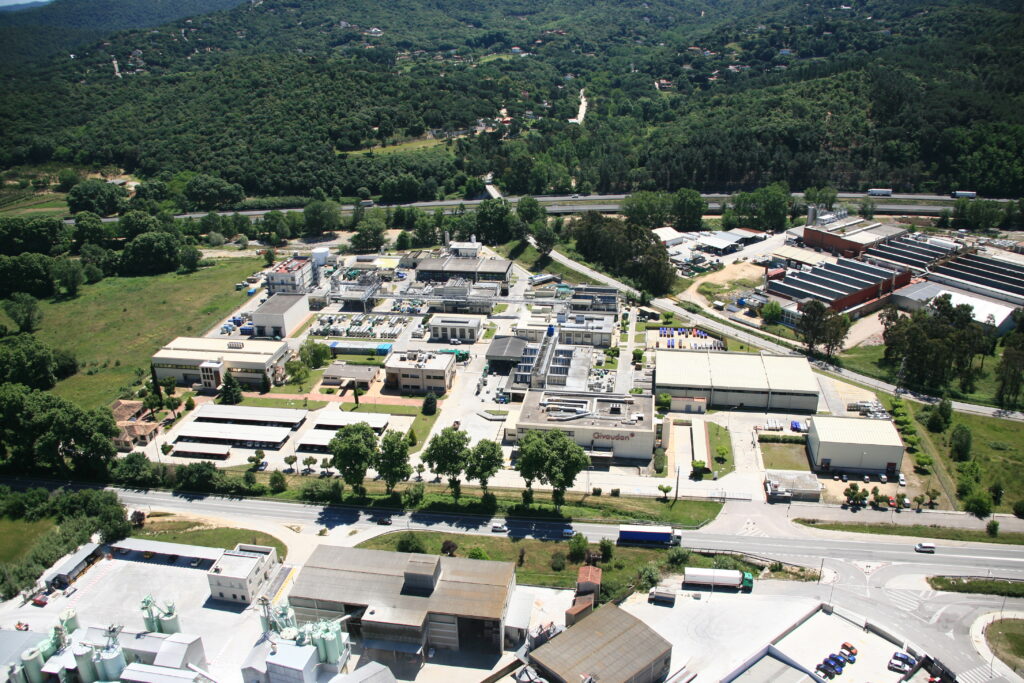

By maximising the use of renewable energy through its unique technology, HyCool aims to minimise greenhouses gas emissions. Givaudan, which itself has a target of reducing absolute Scope 1 and 2 GHG emissions by 30% between 2015 and 2030, is proud to host one of the project’s two pilot sites at its Sant Celoni plant. Givaudan spoke to Jorge Vilaseca, local Project Engineer, to get an update.

Why did Givaudan decide to participate in this project?

The idea was to test HyCool in at least two industries using significant amounts of cooling in their

processes and Givaudan offers a great profile to host one of the pilot sites as a representative of

the chemical industry. We couldn’t pass up the opportunity to participate in this innovative project.

HyCool is particularly attractive to Givaudan for two main reasons. First, our sustainability strategy

A Sense of Tomorrow includes ambitious environmental targets. This project will help us reduce

GHG emissions by a projected 3% for the site and decrease energy consumption in terms of

electricity and gas, helping us towards our goal of 100% renewable electricity by 2025. The

project is totally aligned with our sustainability strategy. Secondly, every Givaudan production

plant needs heating and cooling, and it would be relatively easy to replicate this technology.

HyCool should deliver refrigeration with 25% greater efficiency—this would provide Givaudan a

competitive advantage.

How far along are we in the project?

We have finished the conceptual phase: we have decided where and how to use the cooling

produced, where to install equipment and how to connect it. Now we are looking at detailed

engineering: how to best connect materials, figuring out the best design for the electrical

connections, etc. The one-year installation phase will then start this summer.

What requirements did Sant Celoni have to take into account when planning installation?

One issue was finding a place to install the solar collectors. They require more than 1, 000 m2 of

surface, preferably over a roof. Because of a lack of surface on our buildings, and for safety

reasons, mainly the presence of flammable products, this wasn’t possible, and we had to install

the solar field at ground level. This caused problems such as how to manage shadows of other

buildings that we had to solve.

We also have to comply with all EHS requirements including ensuring a good works plan for

execution. We expect a number of external contractors and companies on site during installation

and we will need to monitor all aspects of their work. We will need to ensure a pre-start safety

review, issue corresponding work permits and make sure we prevent injuries and accidents: we

want to ensure that “Everyone gets Home Safe Everyday”.

Givaudan, which itself has a target of reducing absolute Scope 1 and 2 GHG emissions by 30% between 2015 and 2030, is proud to host one of the project’s two pilot sites at its Sant Celoni plant.

How did consortium partners contribute?

During the initial phase, we worked closely with the equipment companies and engineering and

general contracting partners. This has been a real team effort.

What are the next steps for Givaudan as a pilot site?

The next steps are to finish the installation on time, on budget and safely and then to operate the

machinery and collect data on energy efficiency and ease of use. We have two years of hard work

ahead, but it will be stimulating. As to transferring the technology to other sites – why not? If it is

cost effective, we will be able to use it in countries with even more favourable weather conditions

such as Mexico, South Africa or Singapore.