BY SILVIA JANÉ (European Projects Manager), VEOLIA SERVEIS CATALUNYA

The food sector is making ever increasing demands for cooling in production and product conservation processes. Such a situation represents a challenge to the industry, since higher energy consumption can lead to increased greenhouse gas emissions (CO2, SO2 and NOx), which in turn contribute to global warming of the atmosphere. The HYCOOL project was born from the need to cope with sector demands and to minimise their environmental impact. The aim of the project is to maximise the use of renewable energy sources in industrial cooling.

HYCOOL (Industrial Cooling through Hybrid system based on solar heat) is an innovative project co-financed by the European Union as part of the Horizon 2020, programme for validating an industrial cooling and steam generation system using high temperature solar panels. The project, which commenced in May 2018 and is set to last for three years, is led by Veolia Serveis Catalunya and is made up of another 16 partners from six European countries. HYCOOL has a budget of 7.7 million euros and will be tested in two industrial plants in Catalonia.

The aim of the HYCOOL project is to increase the use of solar heat in industrial processes and show that it is feasible to apply new technologies (understood as a system) to industries with cooling needs with the use of solar energy. One of the advantages offered by HYCOOL is its greater flexibility and capacity for adaptation to different settings thanks to its hybrid pumps, which enable it to work with conventional grid electricity or from renewable systems such as solar energy. Hybrid pumps also provide a more efficient system by doubling the coefficient of performance (COP) of conventional heat pumps.

The advantages of HYCOOL for the food industry

One of the sectors that can most benefit from application of the HYCOOL system is the food industry, since it permits the current recooling plants to be replaced. Such plants are necessary for extracting heat from the production areas or for reducing and/or maintaining the temperature of the food product at low temperatures before, during and after the production process.

The purpose of the cooling required in the food industry is to reduce biochemical and microbiological changes in foodstuffs. This enables the life span of fresh produce and processed foods to be lengthened and can also maintain a given temperature during processing, as is the case in fermentation processes.

There are a multitude of processes in the food sector that require cooling systems, as is the case in the fermentation industry (such as the beer-making sector in their fermentation processes, yeast tanks and product storage), the dairy industry (milk pasteurisation processes, obtaining and concentrating whey, butter production, etc.), the meat processing sector (packaging processes in production and storage of raw materials and end products) and the bread industry (fermentation and storage), etc.

For processes like these, the set point temperatures are variable, which is the case with cooling systems used in the market (evaporative cooling systems, indirect cooling, etc.). The HYCOOL system can reach temperatures of 5ºC or -10ºC, depending on the configuration of the compressor it uses (cascade or pre-cooling mode), which makes it adaptable to almost any process in the food industry.

Bo de Debò: first food company to try out HYCOOL

The expectations for the HYCOOL system are not humble ones: it is hoped that the system shall enable reductions in energy consumption of around 75% and increases in efficiency of 25% in the environments where it is used. To demonstrate this, the company BO DE DEBÒ, in Sant Vicenç de Castellet (Barcelona) was selected as a firm in the food sector to test HYCOOL and confirm the performance expected from the system. The main focus of the activities of BO DE DEBÒ is on preparing high-quality pre-cooked dishes, which requires cooling to be used in its conservation processes for raw materials and end products (between 0 and 4ºC) and in the production and delivery areas (between 8 and 12ºC).

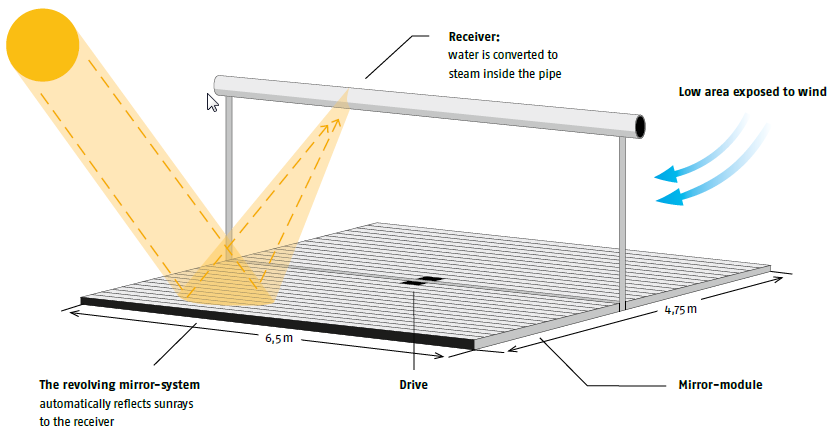

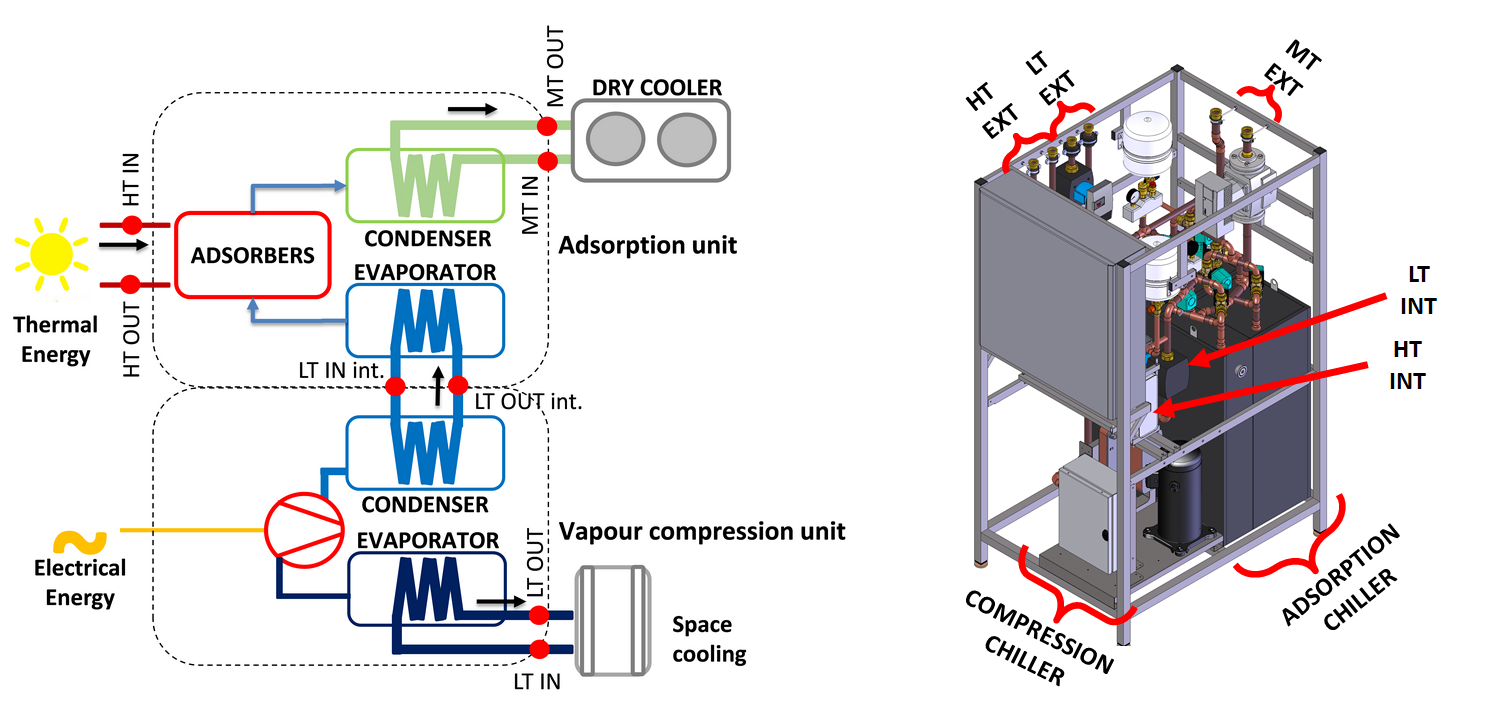

The cooling system operates via solar energy and has two key components: the collectors and the hybrid heat pumps. The Fresnel compact solar collectors -developed by the Austrian company, FRESNEX– have a mirror surface area of 10 m2 and supply the heat source used by the system. They also incorporate a swivelling mirror bearing as the support bearing system for the mirrors, using a hinge line. This innovative feature enables the element’s thermal performance to be increased, as demonstrated in the test institute, where excellent results were obtained. On the other hand, the hybrid heat pumps (or HHP) developed by the German company, FAHRENHEIT are made up of a hybrid adsorption/compressor cooler that can exploit thermal energy (residual heat or other renewable energy sources) and electrical energy to supply cooling energy with high electrical efficiency. The system includes an adsorption module with an evaporator that cools the steam compression cooler condenser, thus improving the electrical COP.

The combination and flexibility offered by the system makes for a wider range of output temperatures, generating a broader spectrum of applications in industrial processes. All these technological innovations shall be put to the test at BO DE DEBÒ, which has a solar field surface area of 400 m2 and receives personalised implementation according to its needs.

Other systems that the system can include are steam generation or uses with hot domestic water, or dissipation systems for heat generated in months when most heat is generated and in new processes. Regardless of the use it will finally be put to, the HYCOOL project aims to show that the system’s flexibility enables it to be adapted to any surroundings and so obtain satisfactory performance.

Veolia’s commitment to promoting this type of projects demonstrates the desire of the company to innovate and constantly seek environmentally sustainable solutions based on renewable energies. The implementation of the HYCOOL project is one example of how collaboration between government and the business community can give form to initiatives that not only mean improvements in a company’s energy consumption results but also in its impact on the environment.

- PRESS ARTICLES REFERRING TO THE SPANISH VERSION OF THIS ARTICLE:

RETEMA, Revista Técnica de Medio Ambiente: Aplicación de nuevas tecnologías para refrigeración en el sector alimentación mediante energía solar

Mundoenergia.com: Veolia lidera el proyecto europeo HYCOOL para maximizar el uso de energías renovables en la refrigeración industrial

Energias-renovables.com: Hycool, un proyecto para maximizar el uso de la energía solar en la refrigeración industrial

Energetica21.com: Veolia fomentará el uso de energía renovable en la refrigeración industrial

Eseficiencia.es: Veolia se suma al proyecto HYCOOL para incrementar el uso de energías renovables en la refrigeración industrial

Residuosprofesional.com: Veolia lidera el proyecto europeo Hycool

Eysmunicipales.es: Veolia lidera el proyecto europeo HYCOOL para maximizar el uso de energías renovables en la refrigeración industrial

Regio7.cat: La bagenca Bo de Debò és pionera a generar fred i vapor amb panells solars