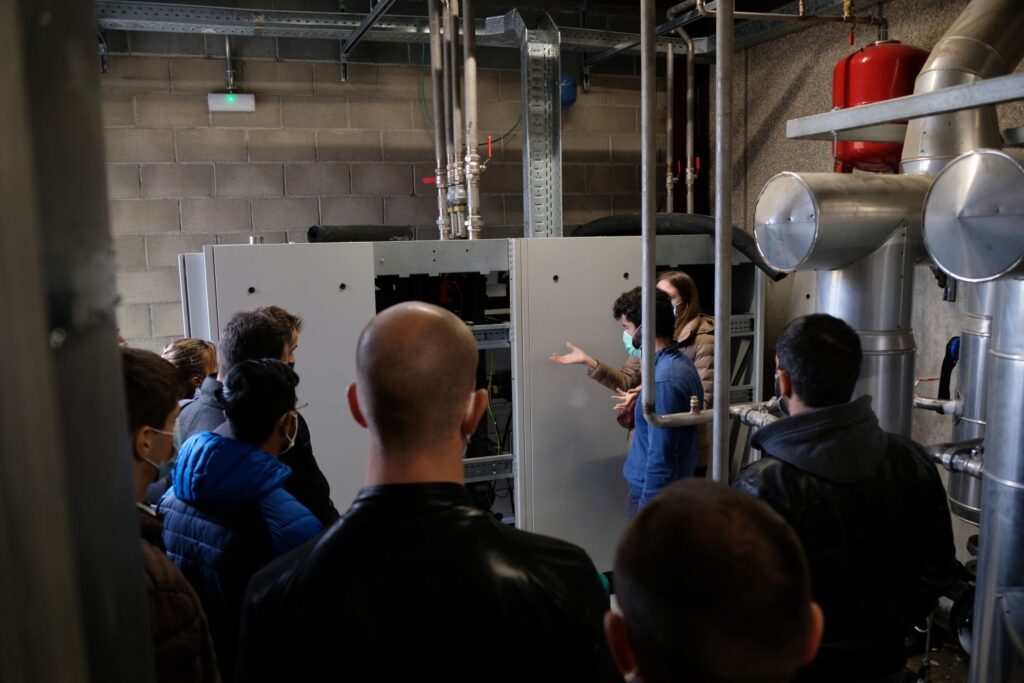

The Hycool Project 9th General Assembly held in Barcelona, Spain, celebrated between 19th and 20th October 2022, brought the consortium together to show the results coming from the preliminary tests, after the commissioning stages at Givaudan and Bo de Debò demo-sites. VEOLIA was in charge to arrange the meeting at their premises in Hospitalet de Llobregat, Barcelona.

The objective of the Assembly was to review and update the project progress after the 8th General Assembly in Halle, Germany, and to discuss about the final delivery of the project results, after the commissioning stage, with the eyes on the closure of the project, under the EU monitoring who will receive and review the success of this action.

The systems installed in Givaudan and Bo de Debò pilots are now providing data from the tests which are running in the solar fields, the heat storage systems and from the hybrid cooling machines.

The assembly sessions covered during the first day, were focused on the status of the different work packages and their level of compliance according to the work plan that had to be extended and modified for the COVID_19 pandemic impact.

This final meeting, nevertheless, has been the starting point to finalise the different open points regarding the evaluation of the key performance indicators, to evaluate the benefits for the industry when using this renewable source of energy, and the life cycle, cost and social impact analysis. At the same time, the end users Givaudan and Bo de Debò had the opportunity to explain their expectations about the HyCool technology installed, and the further profits and the energy savings when the systems are totally operating beyond the EU financial support.

IDP also presented the Virtual Reality environment and the Intelligent Training system developed, and applied to the Ecotherm solar system in Givaudan demo-site. These demonstrations followed to the one performed in COMET within the Workshop on “REPRESENTATIVE OPERATIONAL AND MAINTENANCE ACTIONS OF THE DEMO SITES FACILITIES” held on the 11th of October 2022.

Other topics discussed were focused on the final reports, deliverables and open tasks that must be submitted to the European Commission before the end of the year. There were also planned the final review meeting to be held with the supervision of the Project Officer and that is planned to be performed in Barcelona again, with the aim that the European Commission Representatives can see in person the HyCool installations.

HyCool Project is closing on 31st October 2022 but the final reporting process is extended until December 2022. Now is time to demonstrate how efficient and profitable is the HyCool and thermo-solar energy for the industry, being a pioneering technology for the industrial sector enabling the green energy transition between 2030 and 2050.