Last 12 May 2031, the HyCool consortium held its 6th Virtual General Assembly! Organised as an intense half-day session, this meeting gathered 26 partners online in order to review and discuss project advances with regards to our Solar Heating technologies for Industrial settings. Work package leaders were able to present the progress made with the core technologies, demonstration activities, exploitation, communication, and coordination work packages.

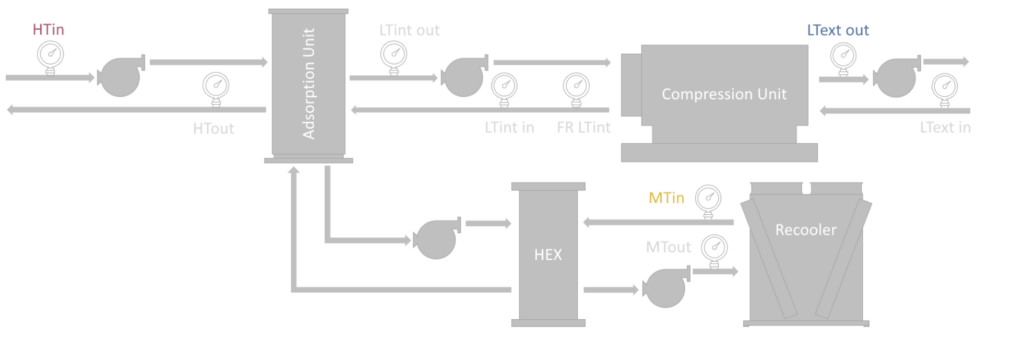

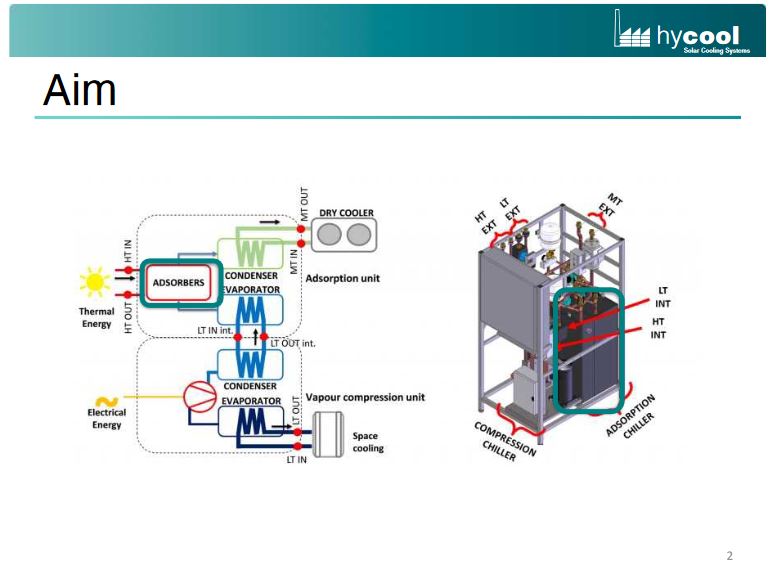

The session started with project coordinator Veolia welcoming us and reviewing the status of the project management work package. After this dive into the more administrative side of the project, we stepped right into the technical workpackages: Empa was able to present the status of their work on the adsorption material characterization protocol and behavior model while Ecotherm presented an update on the energy management system that will soon be installed in both our pilots. Then Veolia updated us on the adavances of the civil works and installations that are ongoing at our two pilot sites, like the recent installation of the anchors at the Givaudan pilot site, for example.

After the more technical presentations, it was time for work packages 7, 8 and 9 that are in charge of environmental and socio-economical analysis, exploitation and communication activities. Highlights presented during these work packages include the ongoing LCA Analysis and our upcoming WSED Workshop with the collaboration of AIT, Ecotherm, Fahrenheit, CNR ITAE and R2M. From the communication standpoint several new materials where presented, including the new Ressource on SHIP page which aims to foster knowledge exchange and synergies with other sister projects and organisations working on promoting the use of Solar Thermal.

The meeting wrapped up with high hopes that next time we might meet again in person and with a clear view of the next steps that will be taken by all partners during the next 6 months.