Title: Analysis of a solar hybrid cooling system for industrial applications

Language: English

Authors: Uli Jakob (*1) and Falko Kiedaisch (*1)

*1: Dr. Jakob energy research GmbH & Co. KG (JER), Pestalozzistr. 3, 71384 Weinstadt (Germany)

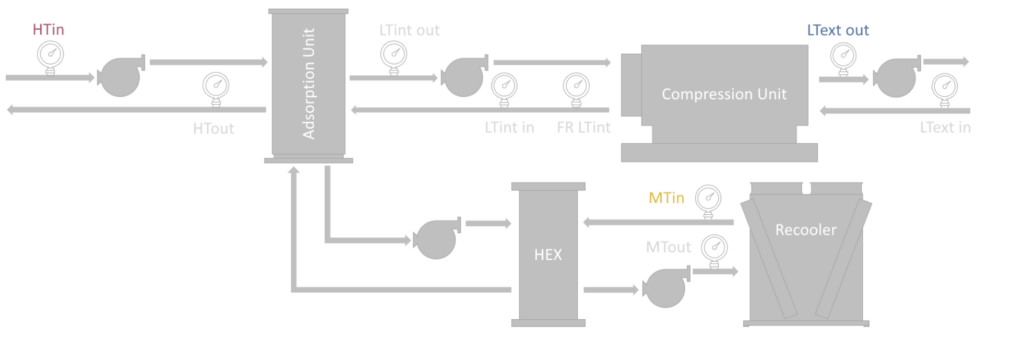

Abstract: This paper presents the analysis of a new Fresnel solar thermal collector (FCSP) system with a Hybrid Heat Pump (HHP) for solar cooling purposes in industry using TRNSYS simulation. The HHP is a combination of a thermally driven adsorption chiller and electric compression chiller in a cascaded configuration, to achieve highly increased Energy Efficiency Ratios (EER) for the operation of the solar assisted HHP system. The benefits of the solar assisted HHP system is mainly based on constantly low heat rejection temperature of the compression chiller, compared to conventional ambient heat rejection systems, as the adsorption chiller is responsible for the heat rejection of the entire hybrid cooling system. The evaluation of a demo case in Barcelona, Spain showed, that EERs between 7-8 can be reached, hence, the electric power consumption of the cooling system can be reduced by 29 % in transitional seasons and by 44 % during summer. As a result of this approach, it is determined that full load operation conditions of minimum 3,800 h and ambient heat rejection

conditions with above 20°C have to occur constantly through operation period, to enable an overall economic operation of the solar assisted HHP System. As an example, for the investigated industry process in Barcelona specific cooling costs of 0.031 EUR/kWh can be reached at operating hours of 4,748 h/a. Moreover, it was analysed that the solar assisted HHP system is likely feasible for the implementation into industrial process typologies with both, heat and cold demands.